Les profilés sont des éléments essentiels de tout projet de construction ou de rénovation, car ils sont fonctionnels, esthétiques et durables. Cependant, leur installation peut présenter des difficultés qui, si elles ne sont pas correctement traitées, compromettent le résultat final. Dans ce guide sur la pose des profilés de construction, nous examinerons les erreurs les plus courantes et proposerons des solutions pratiques pour les éviter, afin de garantir une finition professionnelle et durable.

L’un des problèmes les plus fréquents lors de l’installation de profilés est le choix d’un type qui ne correspond pas aux besoins spécifiques du projet. Par exemple, les profilés conçus pour les zones humides telles que les salles de bains et les douches doivent résister à la corrosion. Se tromper de profilé peut compromettre la fonctionnalité et la durabilité de l’installation. Pour éviter cette erreur, il est essentiel d’évaluer les caractéristiques de l’espace, telles que l’exposition à l’humidité, le niveau de passage et les conditions climatiques.

Les profilés en aluminium d’Euroshrink, spécialement conçus pour les applications dans les zones humides telles que les salles de bains et les douches, sont idéaux pour garantir la durabilité et la fonctionnalité, même dans les conditions les plus exigeantes. En outre, notre catalogue comprend des options spécifiques pour l’extérieur et les zones de passage intense.

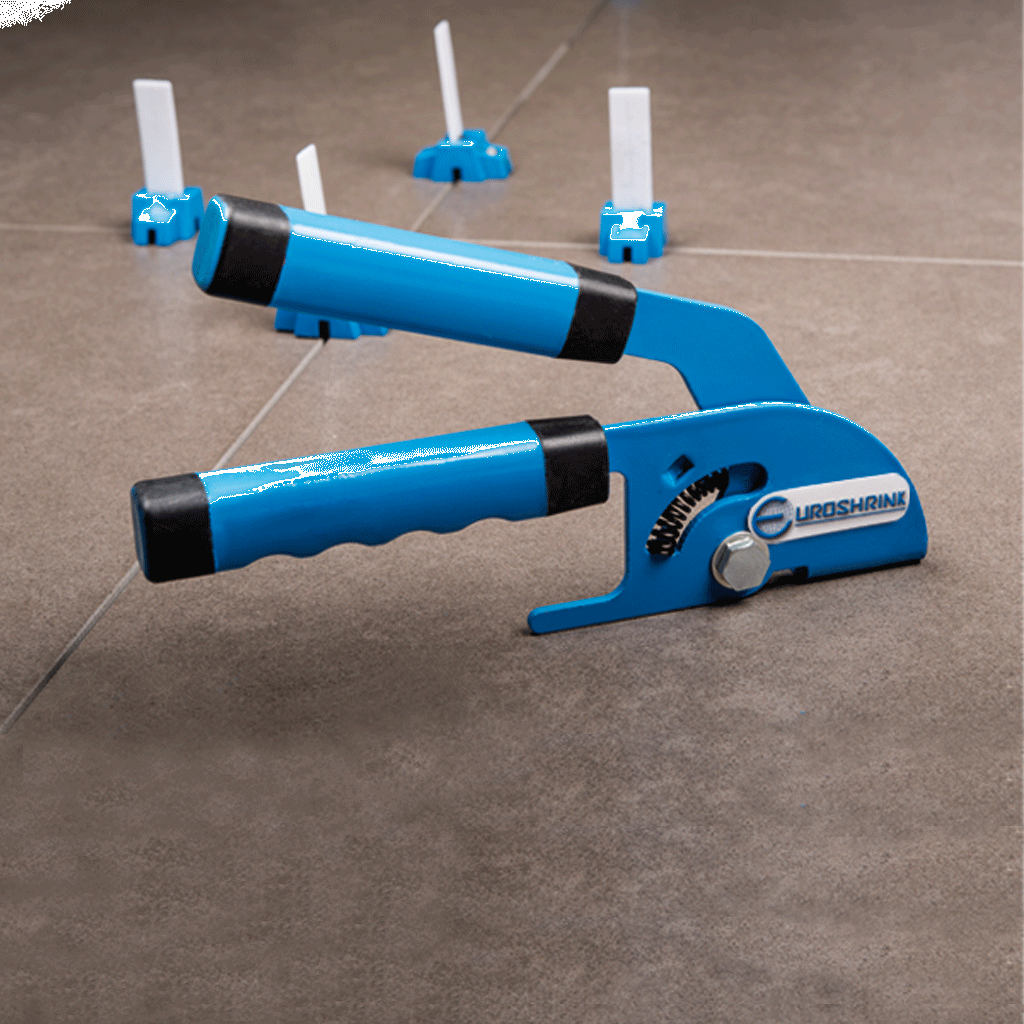

Un problème récurrent est l’absence de préparation adéquate de la surface avant l’installation des profilés. Une surface bien préparée est essentielle pour une finition durable et professionnelle. Les surfaces sales, humides ou irrégulières peuvent nuire à l’adhérence et entraîner des finitions inégales. De telles erreurs peuvent être évitées en s’assurant que la surface est parfaitement propre, sèche et plane avant de commencer l’installation. Des outils tels que le kit de nivellement Euroshrink sont idéaux pour faciliter ce processus et garantir un ajustement précis, corriger les irrégularités et éviter les problèmes pendant le processus d’installation.

L’utilisation d’un adhésif qui n’est pas compatible avec la surface ou le matériau du profilé est une autre erreur fréquente. Cela peut entraîner une mauvaise tenue et réduire considérablement la durabilité de l’installation. Pour éviter ce problème, Euroshrink fabrique ses profilés avec une découpe qui favorise l’adhérence durable de ses profilés. Préparez la surface, ajoutez l’adhésif nécessaire selon les recommandations du fabricant de céramique et appuyez fermement pour que la découpe remplisse sa fonction de préhension. En outre, pour garantir une application correcte et une finition fiable, il est essentiel de suivre les recommandations d’installation du fabricant.

Des profilés mal coupés peuvent entraîner des problèmes tels que des défauts d’alignement ou des écarts visibles entre les pièces, ce qui nuit à la fonctionnalité et à l’esthétique de l’installation. Cette erreur est évitée en utilisant des outils spécialisés tels que des disques à découper et des forets diamantés pour réaliser des coupes nettes et précises. Il est également important de prendre des mesures précises avant de procéder à la découpe, afin de s’assurer que les dimensions sont correctes et de laisser une petite marge pour les ajustements finaux. Prendre le temps de réaliser des coupes précises permet d’obtenir un ajustement parfait et une finition professionnelle.

Les mouvements structurels sont un facteur souvent négligé lors de la pose des profilés. Les structures peuvent se dilater ou se contracter en raison des changements de température, de l’humidité ou du tassement du bâtiment, ce qui peut provoquer des fissures ou des déformations des profilés. Pour éviter ce problème, il est conseillé d’utiliser des profilés avec joints de dilatation conçus pour absorber les mouvements structurels sans compromettre la finition. En outre, le fait de laisser un petit espace entre le profilé et les matériaux environnants permet à la structure de s’adapter naturellement.

Ignorer les spécifications techniques du fabricant est une erreur qui peut compromettre la fonctionnalité et la durabilité des profilés installés. Pour éviter cela, il est essentiel de lire attentivement les instructions d’installation incluses dans la fiche technique du produit qui peut être téléchargée directement sur notre site web, et si nécessaire, de consulter des ressources supplémentaires fournies par le fabricant, telles que des tutoriels ou des manuels techniques. Euroshrink offre une grande variété de ressources pour faciliter le processus d’installation et garantir un bon résultat.

Une autre erreur fréquente consiste à ne pas effectuer d’essai préliminaire avant de fixer définitivement le profilé. Cela peut entraîner des problèmes difficiles à corriger une fois le profilé installé. Il est recommandé de procéder à un essai à sec, c’est-à-dire de positionner le profilé sans appliquer d’adhésif ou de produit d’étanchéité, afin de s’assurer que l’ajustement est correct. Cette étape supplémentaire permet de détecter les éventuels ajustements nécessaires et d’ajuster leur position pour garantir un alignement parfait et une finition propre et professionnelle.

L’esthétique est un aspect fondamental de tout projet, et un profilé mal positionné ou présentant des joints irréguliers visibles peut nuire au résultat final. Il est important de prêter attention aux détails tels que les angles et les joints, en veillant à ce qu’ils soient parfaitement alignés et correctement scellés. L’utilisation de profilés décoratifs vous permet de combiner fonctionnalité et design, en offrant des finitions dans des couleurs et des textures qui s’intègrent parfaitement à tous les styles architecturaux.

L’installation de profilés est un processus qui exige de la minutie, de la planification et l’utilisation de matériaux appropriés. En évitant ces erreurs courantes, vous obtiendrez une finition professionnelle, fonctionnelle et durable. Grâce à ces recommandations et à notre catalogue de solutions innovantes, les professionnels et les amateurs peuvent relever les défis de l’installation de profilés et garantir des résultats exceptionnels dans n’importe quel projet. Une installation soignée et l’utilisation de produits de qualité permettent non seulement d’améliorer le résultat final, mais aussi de garantir une satisfaction à long terme.